The power supply of X‑ray machine plays a pivotal role in the overall performance, efficiency, and reliability of X-ray systems. It serves as the foundation for consistent imaging, safe operation, and long-term functionality. A stable power supply not only ensures precise energy delivery to the X-ray tube and detectors but also protects sensitive internal components from damage caused by electrical fluctuations. In high-demand environments such as hospitals, industrial inspection facilities, and security screening operations, even minor power inconsistencies can lead to blurred images, repeated scans, or premature wear of critical components. Understanding the top factors that contribute to a reliable power supply is essential for operators, engineers, and procurement teams to maintain high-quality imaging and minimize downtime.

1. Consistency in Voltage and Current

A reliable X-ray machine requires constant voltage and current to produce accurate and consistent images. Variations in electrical input can result in uneven X-ray intensity, producing images that are either too dark or too bright, which can compromise diagnostic accuracy or the detection of defects in industrial materials. Maintaining stable voltage and current is also critical to preventing stress on the X-ray tube, control circuits, and detectors, which can lead to early failures or performance degradation.

Advanced power supplies are engineered to maintain consistent output even during heavy workloads, ensuring that the machine delivers precise imaging results across multiple scans or high-throughput applications.

2. Integration with the X-Ray Generator

Seamless integration between the power supply and the X Ray generator manufacturers’ components is essential for smooth, efficient operation. When the power supply and generator are designed to work together, energy delivery is optimized to meet the precise needs of the X-ray tube and detectors. This coordination allows for accurate exposure settings, faster warm-up times, and smoother overall operation.

Poor integration, on the other hand, can lead to voltage mismatches, inconsistent tube output, and even equipment damage over time. By choosing power supplies that are specifically designed or certified to work with the X-ray generator, facilities can ensure that the system operates reliably, produces high-quality images, and minimizes unnecessary wear on critical components, extending the system’s operational lifespan.

3. Quality of Components and Design

The internal components and overall design of a power supply directly influence its reliability. High-quality capacitors, transformers, and electronic control circuits are essential for stable performance, while precision engineering ensures that voltage and current are accurately regulated under various operating conditions. Inferior components can degrade quickly, leading to unstable power output, frequent repairs, and reduced lifespan for the X-ray machine. A robust design not only ensures consistent performance but also supports long-term operational efficiency.

4. Built-In Protection Mechanisms

Advanced power supplies include protective features that safeguard the system against electrical faults and environmental stresses. Overvoltage and undervoltage protections prevent spikes or drops from reaching the sensitive X-ray tube and control circuits, reducing the risk of damage. Short circuit detection and interruption mechanisms provide an additional layer of safety, while thermal management systems prevent overheating during continuous or high-load operations.

These built-in protections ensure that the X-ray system can operate safely even in challenging electrical environments, protecting both personnel and expensive equipment. A well-protected power supply also contributes to consistent image quality, as unexpected electrical disturbances are mitigated before they impact performance.

5. Environmental Stability

X-ray machines often operate in environments where temperature, humidity, and voltage supply can fluctuate. A reliable power supply ensures consistent operation despite these external factors. Power systems that are resilient to environmental changes maintain stable energy output and protect the machine’s internal components from stress caused by temperature variations or moisture. This stability is particularly important in industrial and security applications, where machines may be exposed to harsh or variable conditions.

By tolerating environmental fluctuations, the power supply ensures continuous imaging performance, reduces maintenance requirements, and helps maintain consistent image quality across all operational conditions.

6. Monitoring and Diagnostic Capabilities

Modern X-ray power supplies frequently include monitoring and diagnostic tools that enable operators to track performance and detect issues early. Real-time monitoring of voltage, current, and operational parameters allows for proactive maintenance, preventing minor issues from escalating into major failures. Predictive maintenance enabled by these tools reduces unexpected downtime and extends the lifespan of the machine. Additionally, diagnostic data simplifies troubleshooting by pinpointing the root cause of anomalies, whether related to the power supply, generator, or other components.

7. Energy Efficiency

Optimized energy management is an essential factor in the reliability and cost-effectiveness of X-ray machines. A power supply that delivers only the required energy for each operation minimizes waste and reduces electricity consumption. Efficient energy delivery also helps maintain consistent system performance, even during continuous or high-demand scanning sessions. In addition to operational benefits, energy-efficient power supplies support sustainability initiatives by lowering the carbon footprint of healthcare, industrial, and security facilities.

8. Adaptability Across Applications

X-ray systems are used in a wide variety of applications, including hospitals, laboratories, industrial inspection, and security screening. A versatile power supply can adapt to differing energy requirements, supporting multiple operational modes without compromising reliability. Whether the system is performing high-resolution diagnostic imaging, rapid screening, or non-destructive industrial testing, a well-designed power supply ensures consistent performance, precise control, and safe operation. Adaptability also allows operators to implement specialized protocols, optimize workflows, and maintain high standards of imaging quality across diverse scenarios.

Conclusion

The reliability of an X-ray machine’s power supply is influenced by several interrelated factors, including stable voltage and current, integration with the generator, quality components, protective features, environmental resilience, monitoring capabilities, energy efficiency, and adaptability. By focusing on these factors, operators can ensure consistent imaging performance, reduce maintenance costs, and extend the lifespan of their X-ray systems. A dependable power supply safeguards both the machine and the users, allowing for precise, safe, and efficient imaging operations.

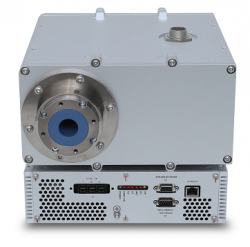

VJ X-Ray is a globally recognized provider of integrated X-ray systems and power supply solutions for medical, industrial, and security applications. With decades of engineering expertise, advanced manufacturing techniques, and a focus on precision, VJ X-Ray delivers high-performance solutions that guarantee consistent image quality, operational reliability, and long-term efficiency. Their systems empower operators to achieve accurate results while ensuring safety and sustainability, making VJ X-Ray a trusted partner for X-ray technology worldwide.