Across modern manufacturing facilities, few systems contribute to workflow efficiency as consistently as the belt conveyor. Its ability to transport materials smoothly, reduce manual handling, and create predictable movement patterns has made it a foundational component in production lines worldwide. Whether used in food processing, consumer goods, pharmaceuticals, or industrial manufacturing, this equipment helps companies improve output speed, minimize labor-intensive tasks, and maintain consistent product quality. By integrating the right conveyor system into their operations, businesses gain better control over timing, flow, and overall process reliability.

The Role of Belt Conveyors in Modern Manufacturing

Continuous Material Movement

The biggest advantage of a belt conveyor is its ability to maintain uninterrupted movement of items throughout a facility. Unlike manual transport or intermittent handling methods, conveyors keep materials in constant motion, reducing bottlenecks and improving synchronization between different production stages. This becomes especially valuable in environments with high throughput requirements, where even minor delays can impact overall productivity.

Because the system can be customized in length, speed, and configuration, it adapts to a variety of workflows. Manufacturers can design straight-line layouts, incline systems, or curved paths to suit the shape and constraints of their facilities. The consistent flow ensures that assembly tasks, inspection stages, and packaging operations always receive materials at the right time, preventing downtime or backup.

Reduced Labor Requirements and Improved Safety

Manual handling is one of the leading causes of workplace injuries and inefficiencies. By incorporating a belt conveyor, organizations can significantly reduce the physical workload placed on employees. Heavy products, fragile items, or repetitive transport tasks are handled mechanically rather than manually, creating safer working conditions.

This system also supports ergonomic workflow design. Instead of workers bending, lifting, or walking long distances with materials, the conveyor brings items directly to each station. This shift not only decreases injury risks but also increases worker productivity by allowing employees to focus on value-added tasks rather than transportation.

Supports Speed and Efficiency in Production

The ability to operate at adjustable speeds is another reason belt conveyors are preferred in fast-paced industries. Production managers can calibrate the conveyor speed to match the output of upstream or downstream machines, ensuring balanced workflow across the entire line. When seasonal demand increases or specialized orders require faster turnaround, the conveyor’s speed can be modified to meet the new requirements without major reconfiguration.

Moreover, the reliability of modern conveyor systems minimizes unscheduled downtime. Built from durable materials and designed for continuous operation, they require relatively low maintenance. When properly serviced, they deliver years of consistent performance, supporting higher output and greater operational stability.

Integration With Quality Control and Automation

Today’s production lines benefit from advanced automation technologies, and belt conveyors play a key role in enabling these systems. Sensors, robotic arms, scanners, and measurement equipment can all be installed along the conveyor path, creating automated checkpoints for quality control. Items can be inspected for size, weight, labeling accuracy, or defects in real time without interrupting the flow of the line.

This integration allows companies to identify issues early, reduce waste, and maintain product uniformity. Additionally, automated sortation features can redirect products to different stations based on size, category, or inspection results, adding further flexibility and precision to the workflow.

Enhancing Packaging Efficiency

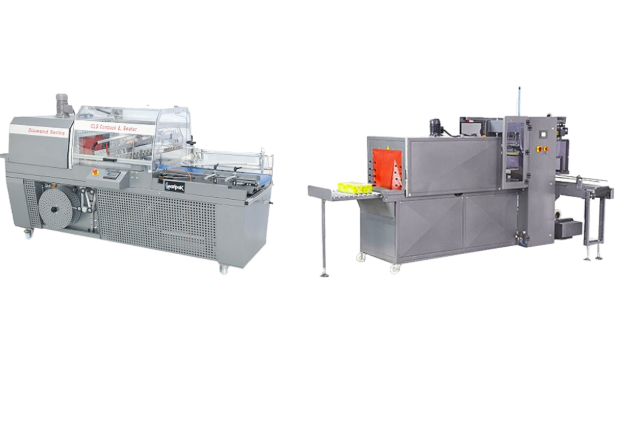

In many facilities, packaging is one of the final and most crucial stages of production. Belt conveyors simplify this step by delivering products directly to packing stations in a consistent, predictable sequence. Workers or automated systems can complete labeling, sealing, and wrapping tasks more efficiently when items arrive in a steady flow.

Conclusion

A belt conveyor remains one of the most reliable and effective tools for streamlining production and packaging workflows. Its ability to ensure continuous movement, reduce labor strain, integrate with automation, and support efficient packing makes it an essential asset for facilities seeking consistent output and improved workflow control. When paired with the right packaging machine, the conveyor system creates a seamless, end-to-end operation that enhances productivity and maintains product quality throughout manufacturing.