Modern packaging operations rely heavily on efficiency, consistency, and smooth material flow to maintain productivity. As production volumes increase and automation becomes more common, material handling systems must support faster processes without compromising accuracy or safety. One solution widely used across industries is the belt conveyor, a fundamental component in many packaging systems that helps streamline workflows and reduce operational strain.

By enabling continuous movement of products through different stages of packaging, belt conveyors play a critical role in maintaining organized, efficient, and scalable production environments.

Understanding How Belt Conveyors Work

A belt conveyor is a mechanical handling system that uses a continuous belt loop, supported by rollers or a flat surface, to transport products from one location to another. The belt is driven by pulleys powered by a motor, allowing controlled and consistent movement along the production line.

In packaging systems, belt conveyors are commonly used to move items between processes such as filling, labeling, sealing, inspection, and final packing. Their simple yet effective design allows them to handle a wide variety of products, making them suitable for many industries, including food processing, pharmaceuticals, manufacturing, and logistics.

Key Benefits of Using a Belt Conveyor in Packaging Operations

Integrating a belt conveyor into a packaging system offers multiple operational advantages that directly impact efficiency and reliability.

Increased Efficiency and Throughput

Belt conveyors provide continuous product movement, eliminating delays caused by manual handling. This uninterrupted flow allows packaging lines to operate at consistent speeds, helping maintain steady output and reduce bottlenecks.

Reduced Dependence on Manual Labor

Manual transportation of products can slow down operations and increase the risk of errors. By automating movement between packaging stages, belt conveyors help reduce repetitive tasks, allowing workers to focus on monitoring quality and managing system performance rather than physical handling.

Improved Workplace Safety

Packaging environments often involve repetitive lifting and movement, which can lead to strain or injury. Belt conveyors reduce the need for manual lifting and carrying, minimizing physical stress on workers and contributing to a safer work environment.

Consistent and Controlled Product Handling

Products move smoothly and evenly on a conveyor belt, reducing sudden stops or impacts that could damage items. This consistency is especially important for fragile goods, sealed packages, or products requiring precise positioning during packaging.

Flexibility and Adaptability in Packaging Systems

One of the strongest advantages of belt conveyors is their adaptability to different production requirements.

Compatibility With Various Product Types

Belt conveyors can transport items of different sizes, shapes, and weights. From lightweight pouches to boxed goods, conveyors can be configured to suit specific product handling needs.

Scalability for Evolving Production Needs

As businesses grow or production demands change, packaging systems must adapt. Belt conveyors offer scalability by allowing additional sections to be added or existing layouts to be modified. This flexibility makes it easier to expand operations without redesigning the entire production line.

Adjustments to belt length, speed, or integration points can accommodate new machinery or increased output, making belt conveyors a practical long-term solution for packaging environments.

Considerations When Selecting a Belt Conveyor

Choosing the right belt conveyor involves evaluating several operational factors:

Belt Material

The belt material should match the product being transported. For example, food-grade belts are required for edible items, while more durable materials may be needed for heavy or abrasive products.

Size and Configuration

The conveyor’s length, width, and height should align with the production layout and product dimensions to ensure smooth operation.

Speed Control and Motor Reliability

Adjustable speed control helps maintain synchronization with other packaging equipment, while reliable motors reduce downtime and maintenance issues.

Maintenance and Durability

Well-designed conveyors with accessible components allow for easier cleaning, inspection, and maintenance, contributing to long-term operational efficiency.

Conclusion

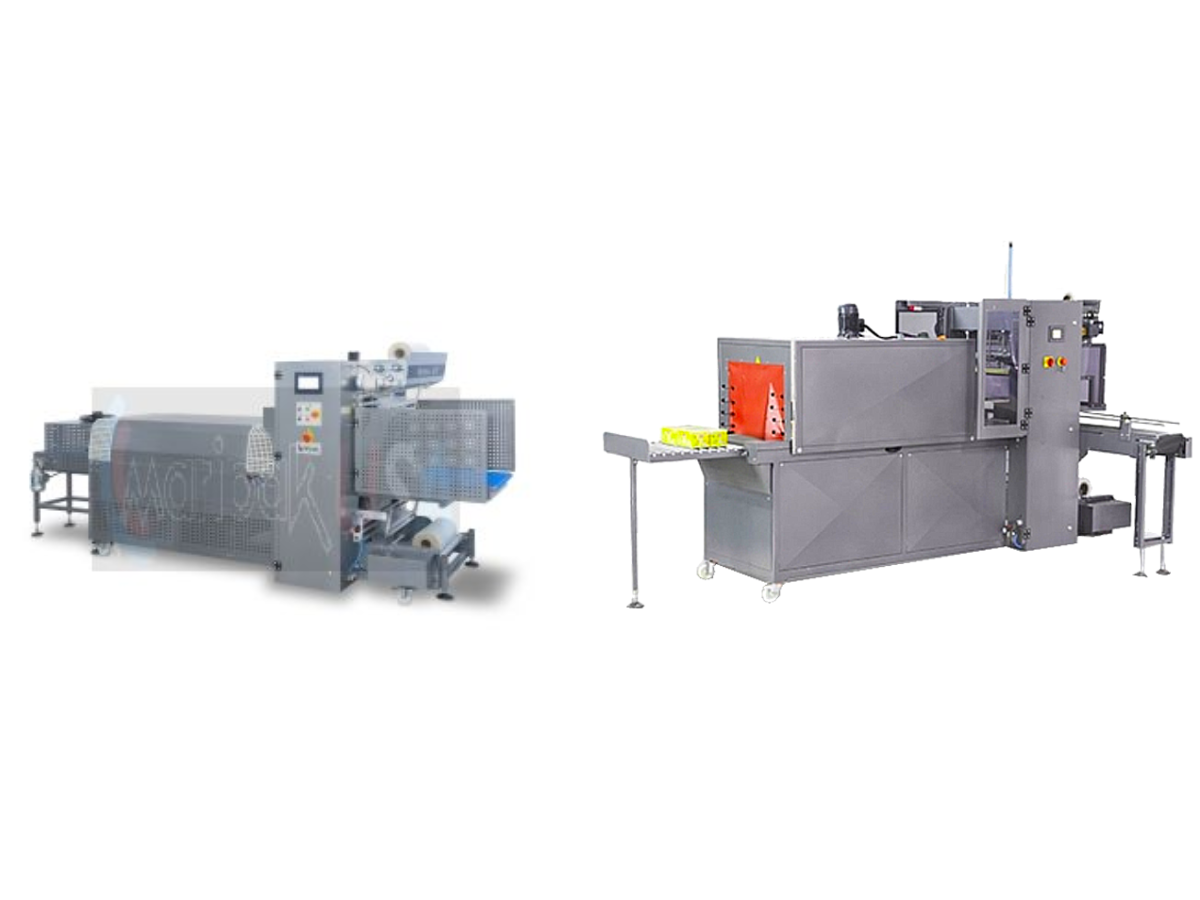

A belt conveyor is an essential element in modern packaging systems, supporting efficient product movement, improved safety, and consistent handling. By reducing manual labor, enhancing workflow coordination, and adapting to various production requirements, belt conveyors help maintain smooth and reliable packaging operations. When integrated thoughtfully alongside a packaging machine, conveyor systems contribute to streamlined processes, improved productivity, and greater operational stability across all stages of packaging.